Australia’s Eris Block 1 rocket, made by Gilmour Space Technologies, had a rough start to its career with a pre-launch failure delaying the vehicle’s maiden flight.

Eris launch vehicle. Courtesy: Gilmore Space Technologies

The nose cone/fairing, triggered by an electrical fault, “pinged” off the rocket prematurely while it was on the pad at the Bowen site at Abbot Point, Queensland, Australia. It was not the ideal introduction to the industry for the new small launch vehicle, which was preparing for its inaugural launch set for 15 May. No damage was caused to the payload – a small test satellite – but the incident has resulted in several weeks delay until another launch can be attempted.

The spacecraft’s first flight, if successful, will be a historic one as it would mark the first orbital launch from Australian soil of a rocket designed and built in the country. Previous attempts at orbital launches from Australia used rockets built by other nations.

Gilmour Space said that the cause of the accidental fairing separation was an unexpected power surge, caused by “electrical backfeed from downstream devices”. Appropriate safety measures have since been introduced.

Gilmour Space may take solace from the knowledge that its rocket is not the first to have ‘blown the top’. According to the Slingshot Seradata database, similar incidents have occurred on other launch vehicles. For example, in December 1999 the launch of a RVSN-40 spacecraft was cancelled when a Rokot vehicle’s pyrotechnic nose cone separation system was set off. Luckily the satellite was not on board at the time.

An earlier incident was even more awkward. A spacecraft fell off its launch vehicle in the first Vanguard launch failure in December 1957. The rocket rose 1.2 metres before exploding and falling back onto its launch pad at Cape Canaveral. The Vanguard TV-3 ‘Grapefruit’ satellite fell from the rocket during its untimely descent and was later found to be fully transmitting in bushes nearby.

More about Eris

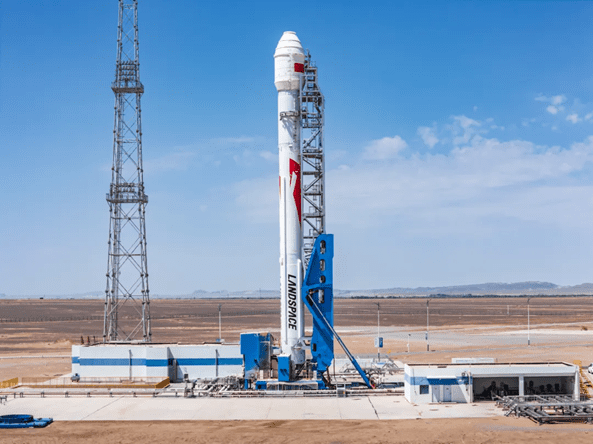

Eris is a three-stage rocket designed to provide rides for small satellites (up to 305 kg) to low Earth orbit (LEO) and to Sun-synchronous orbit (SSO) (up to 215 kg), catering for the constellation market and for individual satellites. Unusually for an orbital launch vehicle, the propulsion system uses a cluster of four 110 kN Sirius hybrid rocket engines, built in-house, for the first stage; a single vacuum version of the Sirius engine for the second stage; and a conventional bi-propellant Phoenix engine for the third stage. Hybrid rockets burn a solid fuel with a liquid oxidiser and are thus fully throttleable and restartable. The company describes its 1.5 m diameter fairing as the best diameter in the rocket’s class for relevant payloads.