Eris, a 25m tall rocket, slowly lifted itself into the air on its maiden flight from Bowen, Abbot Point, in Queensland Australia at 2035 GMT on 29 July.

The rocket, built by Australian startup Gilmour space, cleared its launch pad but then its climb stopped abruptly. Eris then wavered sideways for a second or so, before it crashed back to Earth near the pad. There was no significant explosion on impact, but a fire was observed.

The cause of the failure seemed to be a sequential loss of first-stage thrust. One of the four first-stage engines appeared to shut down, causing the rocket to halt mid-air. This was followed by the apparent failure of another engine which resulted in the vehicle’s weight overcoming the weakened thrust. Eris then fell back and crashed on Earth. A full investigation is underway.

Eris rocket stops its climb as another Sirius engine conks out. Courtesy: Gilmour Space

A video clip of the failure can be seen here.

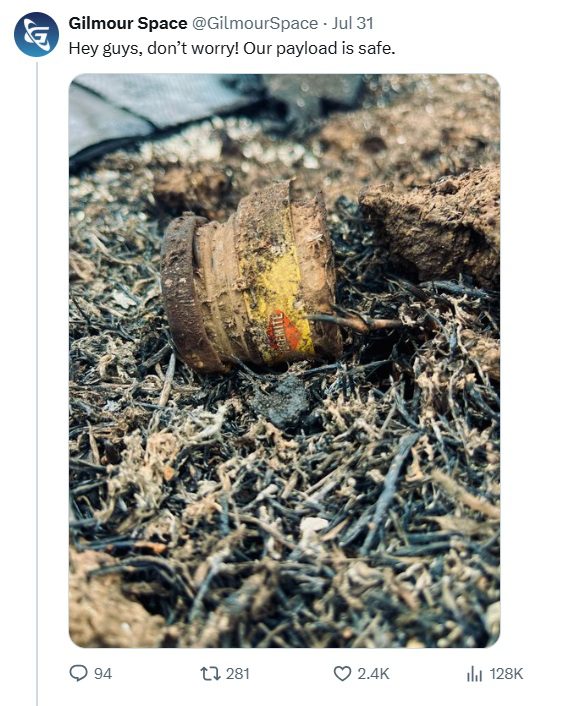

The 110 kN thrust Sirius engines on Eris, built by Gilmour Space, are of an unusual hybrid design: part solid and part liquid propellant. The solid fuel element is 3D printed. Hydrogen peroxide flows through it as the oxidiser. Unlike solid rockets, this throttleable design allows variable control of the thrust. It is suspected that a problem with the oxidiser flow may have caused the engine failures. Eris is thought to have been fitted with instruments to test the launch environment and carried an Australian favourite: a jar of Vegemite spread. Gilmour Space was rather pleased to note that the Vegemite, at least, survived the crash and fire.

Gilmour Space amusingly reported that the Vegemite ‘payload’ survived the fiery Eris launch failure. Courtesy: Gilmour Space/X

Eris is a three-stage rocket designed to provide rides for small satellites (up to 305 kg) to low Earth orbit (LEO) and to Sun-synchronous orbit (SSO) (up to 215 kg). It caters to the constellation market as well as individual satellite launches. The first-stage propulsion system uses a cluster of four of the Sirius hybrid rocket engines. The second-stage uses a single vacuum-optimised version of the Sirius engine. Finally, a conventional bi-propellant Phoenix engine is used for the third-stage. The company describes its 1.5 m diameter fairing as the best in the rocket’s class for relevant payloads.

The launch had a series of delays. Some were caused by high winds, while one was forced by the accidental release of the fairing while the rocket was still on the grounded.

Maiden flight failures of brand-new rockets are common. The Slingshot Seradata database has a failure rate for first flights as 45%.